Waricam software

In addition to our WARICUT® water jet cutting systems, we also supply our “WARICAM” CAD/CAM software as an option. WARICAM is available in various versions, from the Standard to the Professional version.

In order to offer our customers as much comfort as possible, our WARICAM programming system has been delivered for years only as a professional version (full expansion stage). Only a few functions such as the bevel module for 3D systems and the label module are excluded.

Special functions, PPS-connections and various postprocessors (water jet, laser, plasma, oxyfuel cutting systems) can be programmed by us after consultation.

WARICAM is an effective network-compatible NC programming system with design (CAD) and single-part technology (CAM), with manual and fully automatic real contour nesting, economy cut nesting, administration for orders, parts, sheets, plans and NC codes, for the production of single parts, small and large series, tube cutting. Interfaces are:

e.g. dxf, dwg, igs (further interfaces on request)

The functional scope of the software is determined according to customer requirements. If you would like to know more about the extensive WARICAM functionality, we will be happy to send you further information.

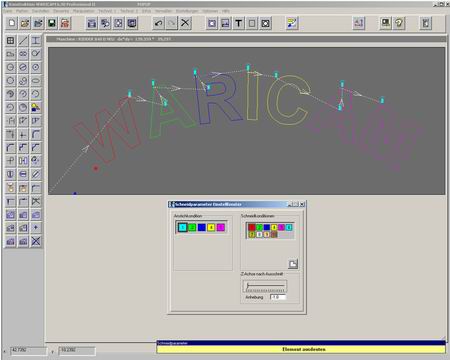

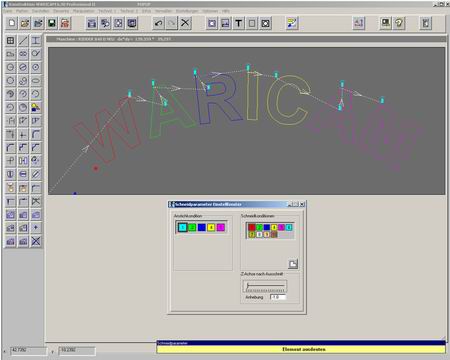

WARICAM Design

WARICAM surface “Construction” with CAD module and various CAM functions, for example the contour or element by element assignment of different cutting conditions (qualities) or the assignment of flags, tapping and cutting conditions automatically according to material and thickness and much more.

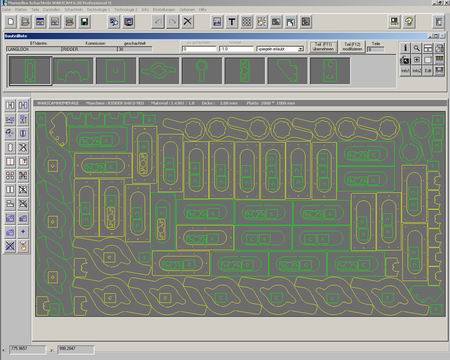

WARICAM manual and automatic nesting

WARICAM surface manual nesting

In Manual Nesting, individual parts can be placed on a selected sheet in the draw or bump mode with collision control and processing sequence.

In addition, the user has the Contour Nesting function available, with which selected parts can also be automatically nested on the displayed sheet in Manual Nesting.

Other available WARICAM functions:

- WARICAM bevel module: simple design of bevel parts for 3D Waricut machines

- WARICAM Professional 3: CAM module for complex cutting tasks in 3D