WARICUT expert systems

RIDDER has developed the WARICUT® Expert System especially for high-pressure waterjet cutting systems and offers the user a comfortable operating guidance.

Here is just a small excerpt of the large range of functions:

- Target-actual value display for: cutting pressure, abrasive, feeder, axes

- Function keys for test run, block cutting valve, save zero point

- Cutting parameter calculation for different quality requirements

- Nozzle abrasive metering system monitoring

- Collision monitoring

- Online correction for feeder, pressure, spacing and abrasive

- Program scan for simple and fast moving to interrupt points

- BDE (Borland Database Engine) for high pressure pump, cutting nozzle, program run times, job times

WARICUT Information system

Messages (error messages and job completion messages) are transmitted directly from the cutting system by telephone to the machine operator (telephone connection and/or Internet access required)

WARICUT Job list

Using the WARICUT® Job list, up to four different or the same four cutting programs can be automatically processed one after the other.

WARICUT Simulation

Workpiece contours are displayed before the cutting and are traced online during the machining.

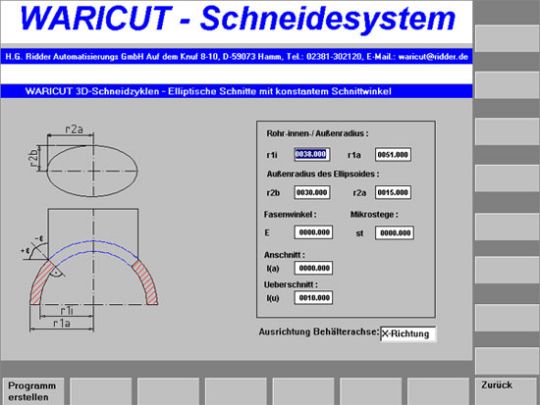

WARICUT Cutting cycles

Using WARICUT® Cutting cycles, the following cutting contours can be easily programmed directly on the machine by entering parameters.

Single cuts and multiple cuts for the following contours: Circle, rectangle, ring, horizontal groove, triangle, vertical groove, trapezoid, flange, ellipse.