WARICUT highlights

Below are the essential details of the standard basic equipment of every abrasive waterjet cutting system from H.G. RIDDER

In addition, some of the most important options are listed with which our systems can be individually extended.

If you require further information, please contact us.

WARICUT® Standard version

- Machine frame and basin basically separate

- Bridge always in gantry construction, no cantilever

- all machine frame and bridge components are welded, annealed, milled, ground and scraped (steel)

- Prepared for later conversion or retrofitting to 3D cutting

- Stable cutting basin made of stainless steel with surrounding metal splash guard (Underwater cutting has been possible with every system since 1990). Each cutting basin also has easy-to-disassemble front and rear bulkhead plates for cutting extra-long components. M12 threaded bushes all around for clamping of fixtures and stops.

- Cutting basin prepared for the connection of a WARICUT ® – desludging plant (picture 1)

- Cutting basin prepared for retrofitting CNC pipe cutting

- CNC control SIEMENS SINUMERIK 840D sl (PCU computer with SSD hard disk)

- Movable control panel (with Siemens control panel, machine control panel, hand wheel etc.)

- Central control of all components via the WARICUT ®- Expert System, the comfortable user interface for waterjet cutting from RIDDER – incl. cutting parameters – calculation, job list, cutting cycles, control of print and abrasive quantity, etc,

- Teleservice (ISDN) and network standard

- All axes CNC controlled, Digital three-phase motors, Gantry drives

- High-precision ball screws and linear guides

- Fully automatic and conventional cutting operation

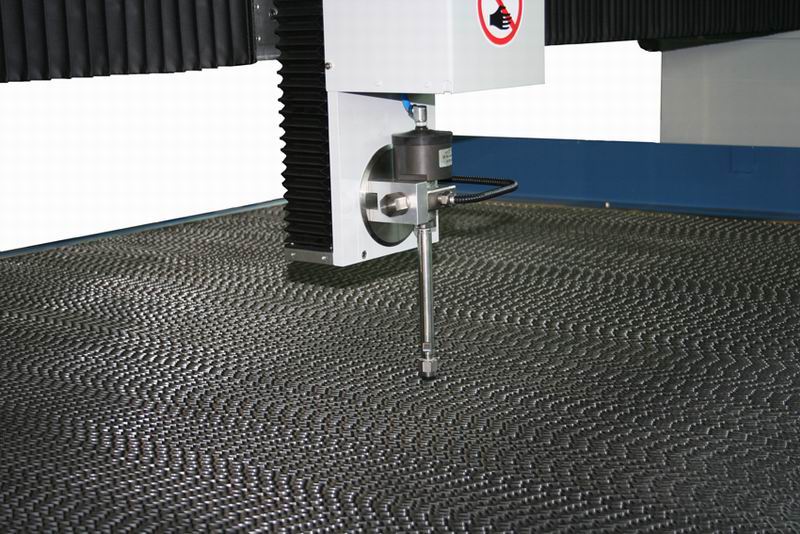

- Differential cutting head guide

- Abrasive silo 2 tons

- Fully automatic abrasive dosing (since 1990 with every system!) incl. humidity sensor

- Alignable 2D cutting head with angle adjustment +/- 45

- Abrasive cutting head – Monitoring

- Pure water cutting head included

- Infinitely programmable cutting pressure adjustment via proportional valve technology incl. electronic high-pressure actual value recording

- Fully automatic central lubrication incl. monitoring

- Light barrier safety device

- All high pressure tubes made of special and durable HP160

- Compressed air and water pistol on the machine frame

- Tools for machine and pump including water and abrasive nozzles

und much more…

WARICUT® System options

(also for later retrofitting by the customer)

- additional 2D and/or 3D cutting axes

- 3D measuring axis for automatic component measurement

- CNC pipe cutting axis

- 4000 or 6000 bar cutting technology for 2D and 3D

- Micro-cutting (possible on every WARICUT ® – waterjet system by means of an upgrade kit)

- special table supports for abrasive cutting

- fully automatic WARICUT ® – desludging plants (picture 1) – proven for over 20 years

- special table supports for pure water cutting (picture 2)

- Sliding and shuttle table systems

- Catcher systems / Suction systems

- manual and automatic clamping systems

- automatic loading and unloading systems (picture 3)

- extensive filter technology for pure water and abrasive cutting systems (also filtration of heavy metals)

- Handheld terminals

- pneumatic or electric high-performance drilling axes incl. cooling water (Fig. 4)

- automatic and comfortable height scanning

- electronic collision sensors

- Alignment laser

- fully automatic abrasive silo preselection for the use of different grit sizes

- 3D CAM systems for complex cutting tasks in space

- 3D measuring probe incl., measuring software

- 3D Teaching Software

- special operating software for sample production (tensile samples etc.)

- extensive BDE software

- extensive PPS connections

- Creation of special postprocessors

- Pump synchronisation controls

- Special requests are always possible – from the use of special electrical components according to the customer’s standard to individual painting

and much more…