Manufacturer of the WARICUT 2D & 3D waterjet cutting machines!

German quality product! 3 years warranty! Construction – Manufacturing – Service – Everything from one source!

Welcome to the company

H.G. RIDDER Automatisierungs-GmbH!

The company H.G. RIDDER Automatisierungs-GmbH has been manufacturing high-quality WARICUT waterjet cutting systems since 1991 and is thus one of the first system providers on the German market for waterjet cutting machines!

This special field developed from our business field, which has been active since 1980, the automation and overhaul of machine tools and the construction of special purpose machines. Our customers worldwide benefit from this wealth of experience!

We are active in the following business areas for you:

Services:

- Laser measurement of machine tools

- Mechanical machining

- Installations (electrical / mechanical)

- Machine tools / systems service

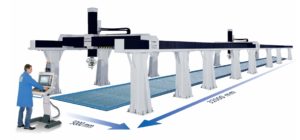

WARICUT Waterjet cutting systems made in Germany by H.G. RIDDER – the professional solution!

Precise, ecofriendly and simply unbelievable. Industrial high pressure waterjet cutter are cutting massive steel parts like thin paper. This applies also for extremely heavy fire doors. WARICUT is the registered trademark of the worldwide established cutting technology in the range of waterjet cutting systems. It is an ecofriendly, cold and high-precision technology – whereby almost all materials can be cut without heat generation, deformation and only few burr. Processing of various thicknesses in 2D or 3D is also possible. The company H. G. RIDDER Automatisierungs-GmbH is a recognized specialist in the field of waterjet cutting with WARICUT machines.

First Class Service: WARICUT systems, upon customer’s special request

Do you have special requirements? RIDDER‘s manufacturing of special purpose machines makes it possible.

Company H.G. RIDDER offers its customers an incredible service: each WARICUT-waterjet cutting machine can be constructed individually according to customer request – as a single system, multi-head system with 2D or 3D or a combination of both types.

Due to the most modern high-pressure pumps a pressure up to 6000 bar can be produced for a powerful high-pressure water jet.

Furthermore there are many other equipment possibilities for waterjet cutting machines available and also the automation lets its own idea a maximum flexibility. But company RIDDER not only produces machines to customer request, a professional retrofit of machine tools belongs to a subject field of the company.

Pure water cutting technology and abrasive cutting technology

The future lies in waterjet cutting and material processing. A distinction has to be made between two technologies. The pure water cut and the abrasive cut. As the name already suggests the pure water jet cuts only with clear water while abrasive cutting feeds an abrasive medium inside a mixing chamber to the cutting head. It is a fine-grain abrasive. Pure water cutting is suitable for the following materials: plastics, foil slide, food, rubber, textiles, leather, wood, laminate, foam plastic, paperboard and paper. And the abrasive cutting technology is used for the following materials: stainless steel, steel, hastelloy, hardox, titanium, aluminum, nonferrous heavy metal, plastics, natural stone, flagstones, glass, acrylic, composites. Waterjet Systems or Watercut Systems makes a small kerf width possible – and not at least waterjet cutting does not include further material costs.

Micro waterjet cutting for the highest precision

Due to the Fine Cut Waterjet procedure very precise cuts with very small kerf widths can be carried out. The company RIDDER offers the industry – with its manufacturing of special purpose machines and automation – excellent solutions for micro cutting and fine waterjet machines. A fine-cut waterjet machine works with a cutting jet with a very small diameter. Therefore, fine cutting enters a new dimension and further application fields in which industry-standard waterjet cutting systems did not have application possibilities.

Reference lists and information material

…you can request directly via our contact form: